股票代码:833352

中文|

Modern injection molding industry is a combination production enterprises of technology intensive and labor intensive, and the production process is semi-automated.Technical management in injection molding industry involves a wide range of aspects, the process is very complex, including raw material performance, finished product structure and mold, raw material ratio, machine performance, workshop safety management, injection molding product quality and some many other aspects of knowledge.Now with the rise in the price of plastic raw materials and labor wages, the original boot that is profitable times have passed. Considered poor management, mold wear, scrapped products and other factors, it may results in many enterprises have no profit at all.The management of Injection molding production process is a more systematic project, because of the industry is relatively special, management is responsible correspondingly. only to control each process can gain profits.

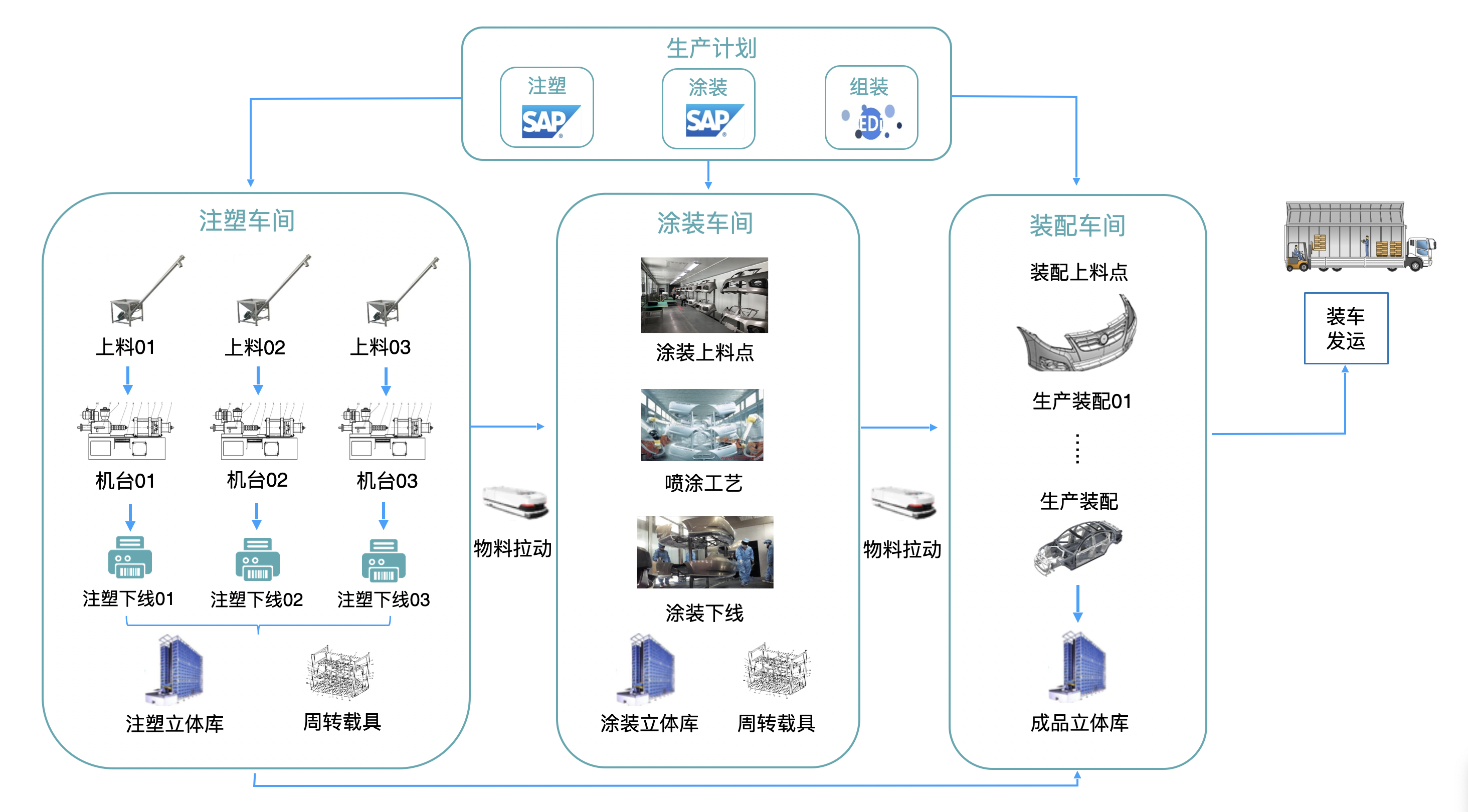

Assembly manufacturing industry demand:

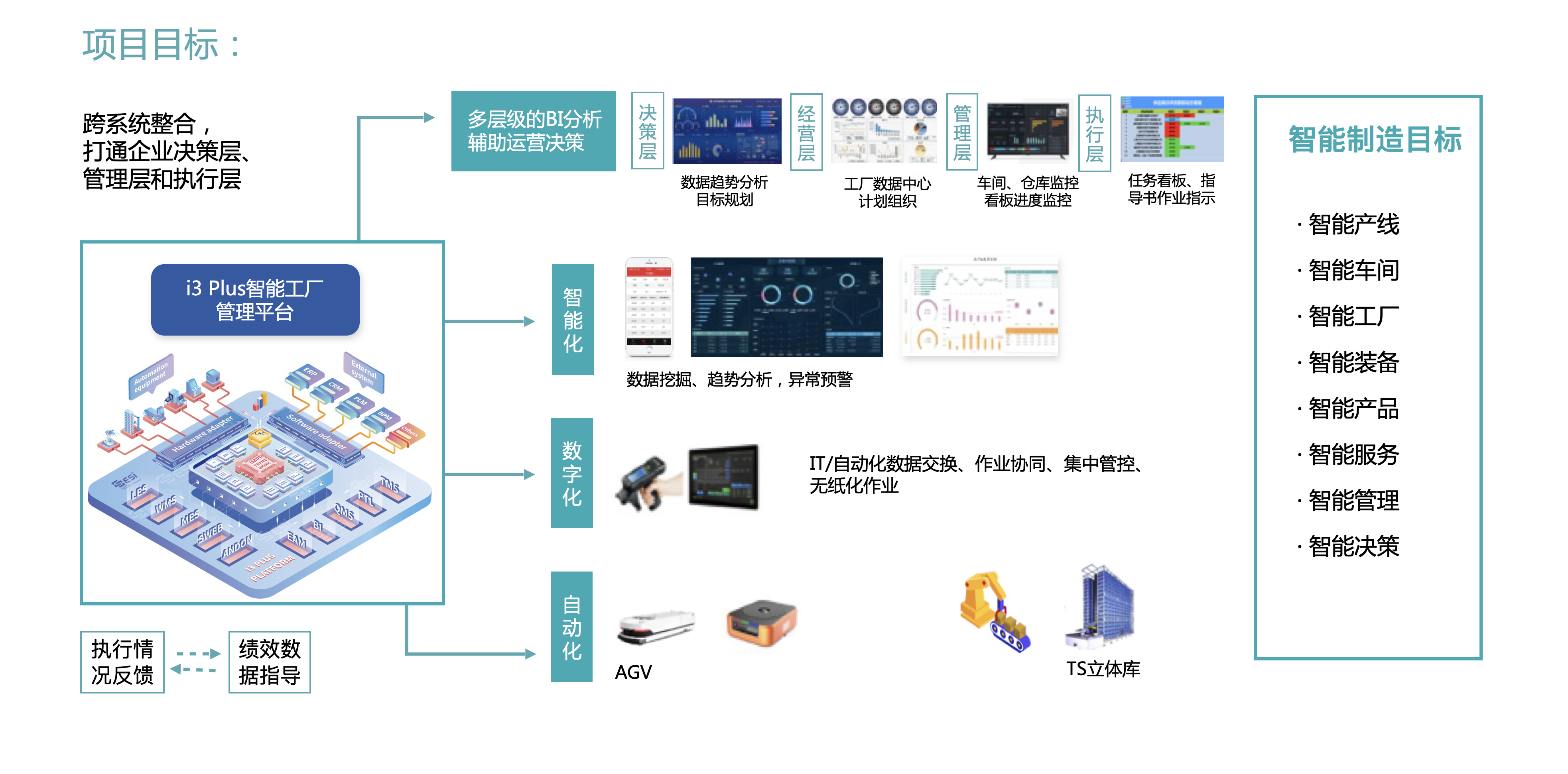

· Under the industry characteristics and society development , the bottleneck of the traditional injection molding industry has gradually emerged. In order to set up the competitiveness of the whole enterprise in the industry and achieve long-term business objectives, it is necessary to keep up with the pace of the society, and it has become an inevitable trend to develop toward industry 4.0 information construction.

· By implementing the enterprise information construction, realizing automation production, the whole process of traceability, equipment data acquisition, real-time data collecting a large number of production, and the real-time analysis, data processing, through the information system can adapt to changing complex process and made into requirements, to quickly build process modeling and process configuration, increase efficiency, improve profit margins, Has become the inevitable demand and desire of industry enterprises.

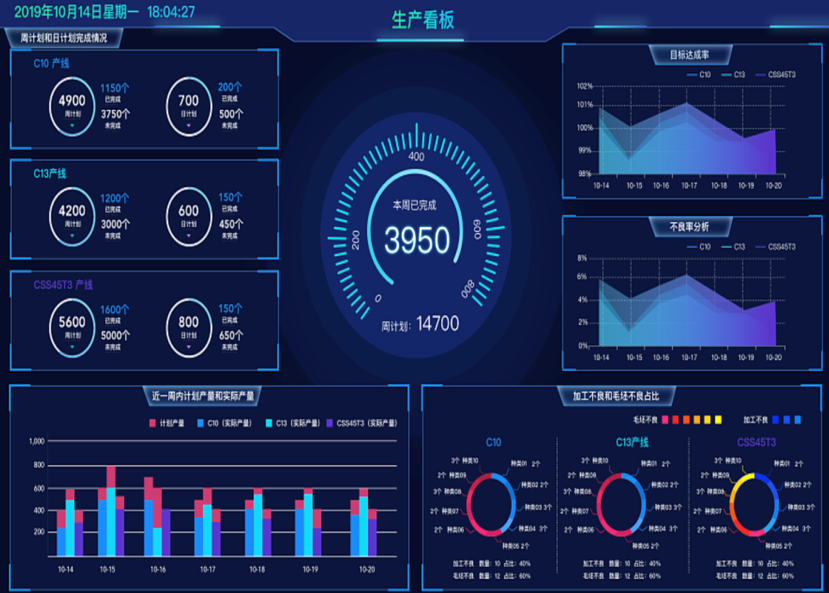

"smart number" management of Enterprise :Multi-dimensional monitoring of plant operation status (production, logistics, equipment, quality, safety, etc.)