股票代码:833352

中文|

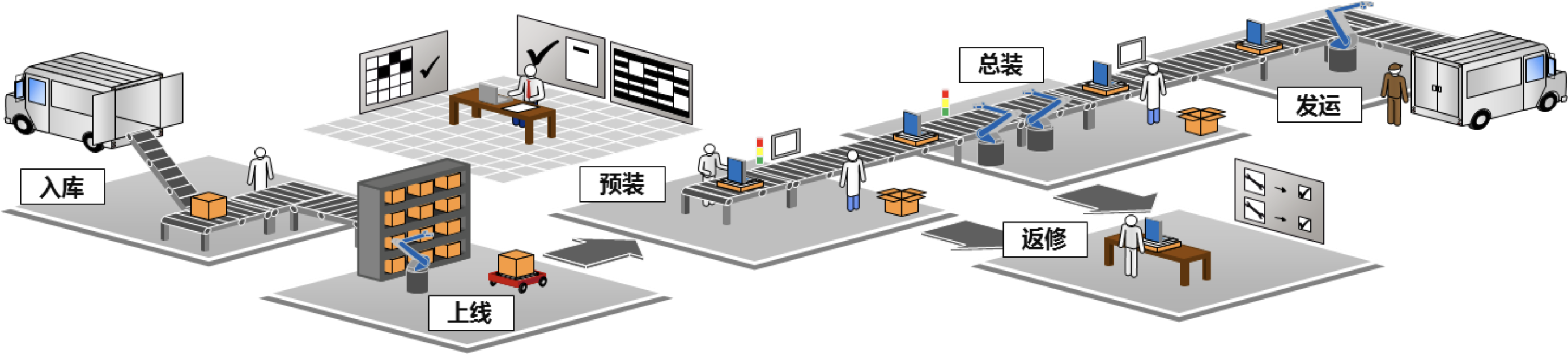

The automobile industry is a comprehensive enterprise based on many related industries and technologies. Car parts include thousands of different parts ranging from floors to screws. All kinds of machining techniques are needed from rough machining to complete vehicle assembly. The actual automobile production process is a collaboration of several different specialized production plants (workshops). In order to produce automobiles economically and efficiently, these specialized production plants (workshops) organize production and cooperate according to the principle of product cooperation. Generally speaking, the engine, transmission, axle, body and other main assembly by the enterprise's own manufacturing, but tires, glass, electrical appliances, body interior parts and other small parts, etc., by professional factory cooperation production.

· The automobile industry plays an important role in the economic development of developed countries:

· In the output value and sales revenue, the automotive industry accounts for a large proportion.

· The development of automobile industry will certainly promote the development of many related industries.

· The automobile industry is a comprehensive assembly industry, a car is composed of tens of thousands of parts, each automobile main engine factory has a large number of related parts factory.

· The automotive industry is highly technology-intensive, concentrating new materials, new equipment, new processes and new technologies in many scientific fields.

Solutions:

· Car interior

Dashboard, secondary dashboard

Door inner panel, lighting technology

· Car seat

Whole chairs: order analysis, work order release, data collection and control in production process, JIS shipping, quality traceability and whole process control;

Carrier: control and traceability of punching, welding, assembling, material pulling, melting depth scrapping, etc.

Foaming: manage mold change, quality and casting information collection and backwash through production plan control, reasonable arrangement of production plan, electronic control and collection of chemical ingredients;

Headrest: PIP foam molding, information process control and data collection;

Face cover: including cutting, trimming, sewing, edge sealing and other processes, through the system control in accordance with customer production plan and a variety of product configuration requirements for verification and material pulling.

· Cockpit electronics: Provide global automotive manufacturers with integrated cockpit electronics and in-car control module development and manufacturing, including mechanical design, electronic design, software development, system integration and experimental verification.

Driving information

Audio entertainment

Control module

· Passive safety

Airbag

Coiler and plug lock

Constrain the integrated system

· Car exterior

Bumper

Composite tailgate

Composite fin steering wheel