股票代码:833352

中文|

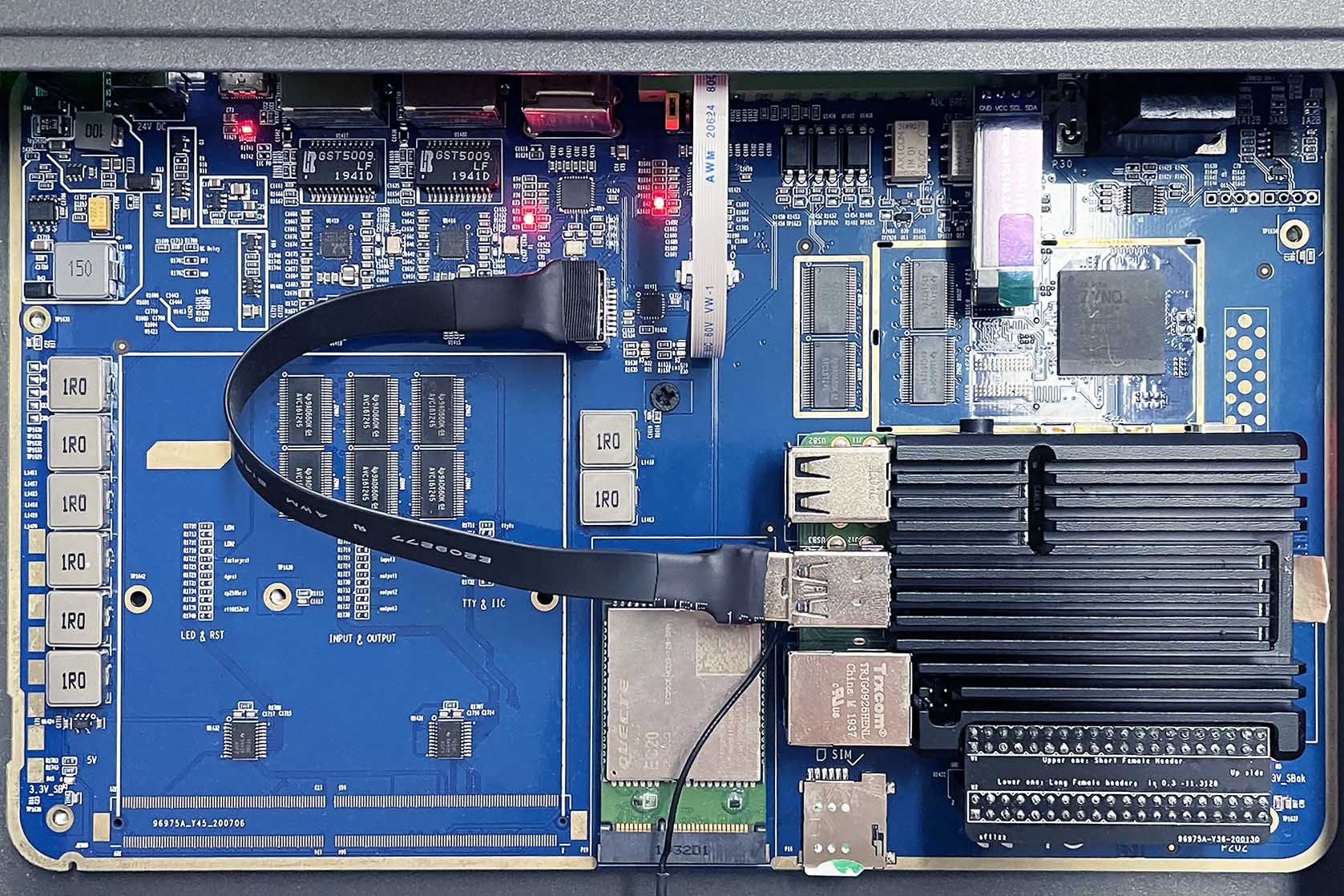

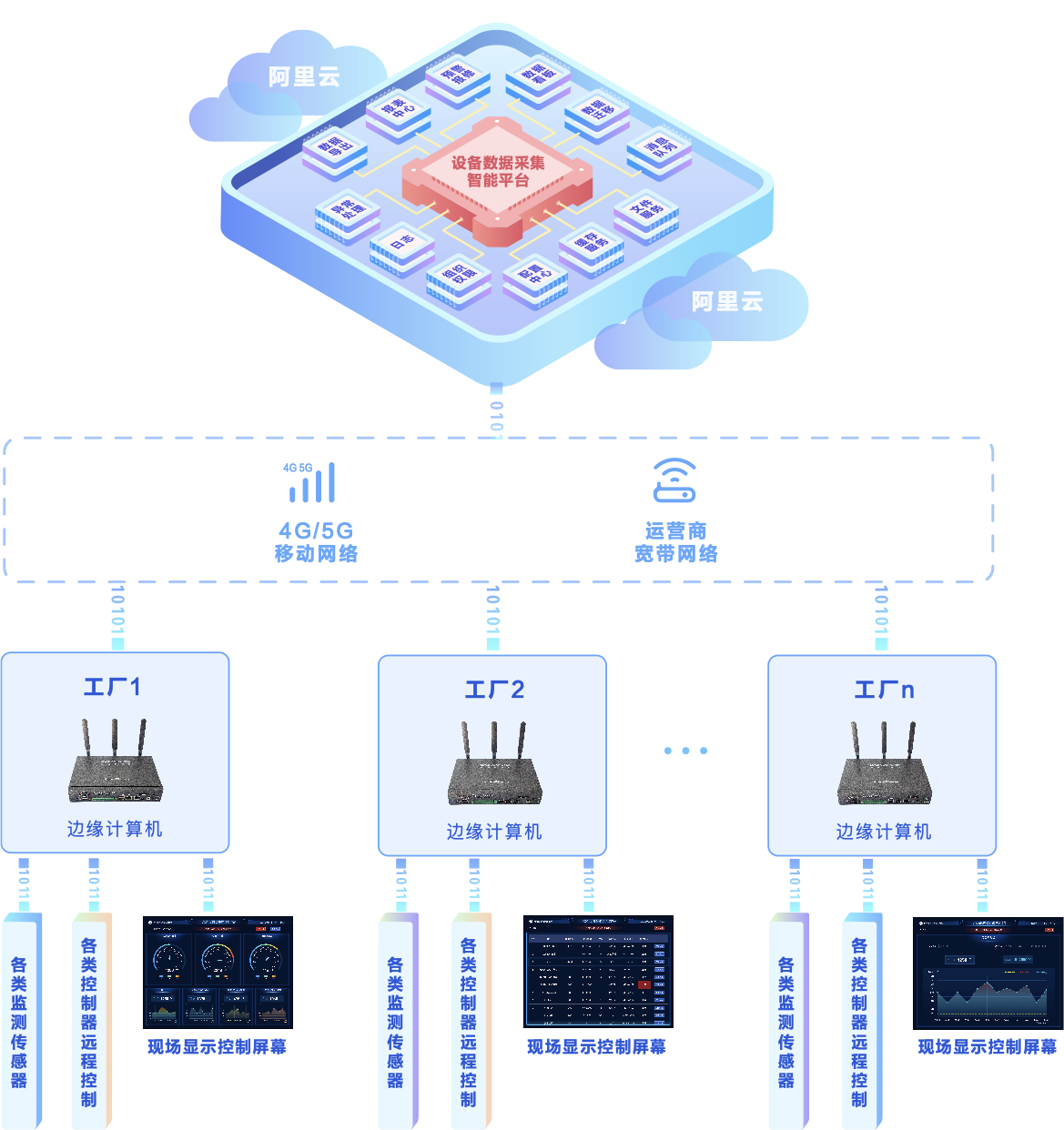

Equipment data acquisition intelligence is an analysis terminal that has the functions of recording and analyzing the production process of equipment or the status data of on-site recording and off-line analysis of machine equipment. It has a wide range of applications in many fields. In recent years, the development trend of intelligent solutions for equipment data acquisition is to simplify terminal structure to replace complex and inflexible field wiring. Using more advanced modular structure, according to different application requirements, by simply increasing and changing modules, combined with system programming, you can expand or modify the system to meet the production process needs of different enterprises, in industry 4.0 production intelligent manufacturing monitoring system plays an important role. The intelligent solution of equipment data acquisition is based on MES system and other platform software to obtain comprehensive, accurate and reliable data and create more economic benefits for processing and manufacturing enterprises. "Let the right data, at the right time, in the right way, automatically delivered to the right people and machines, in order to optimize the efficiency of resource allocation."

Solution:

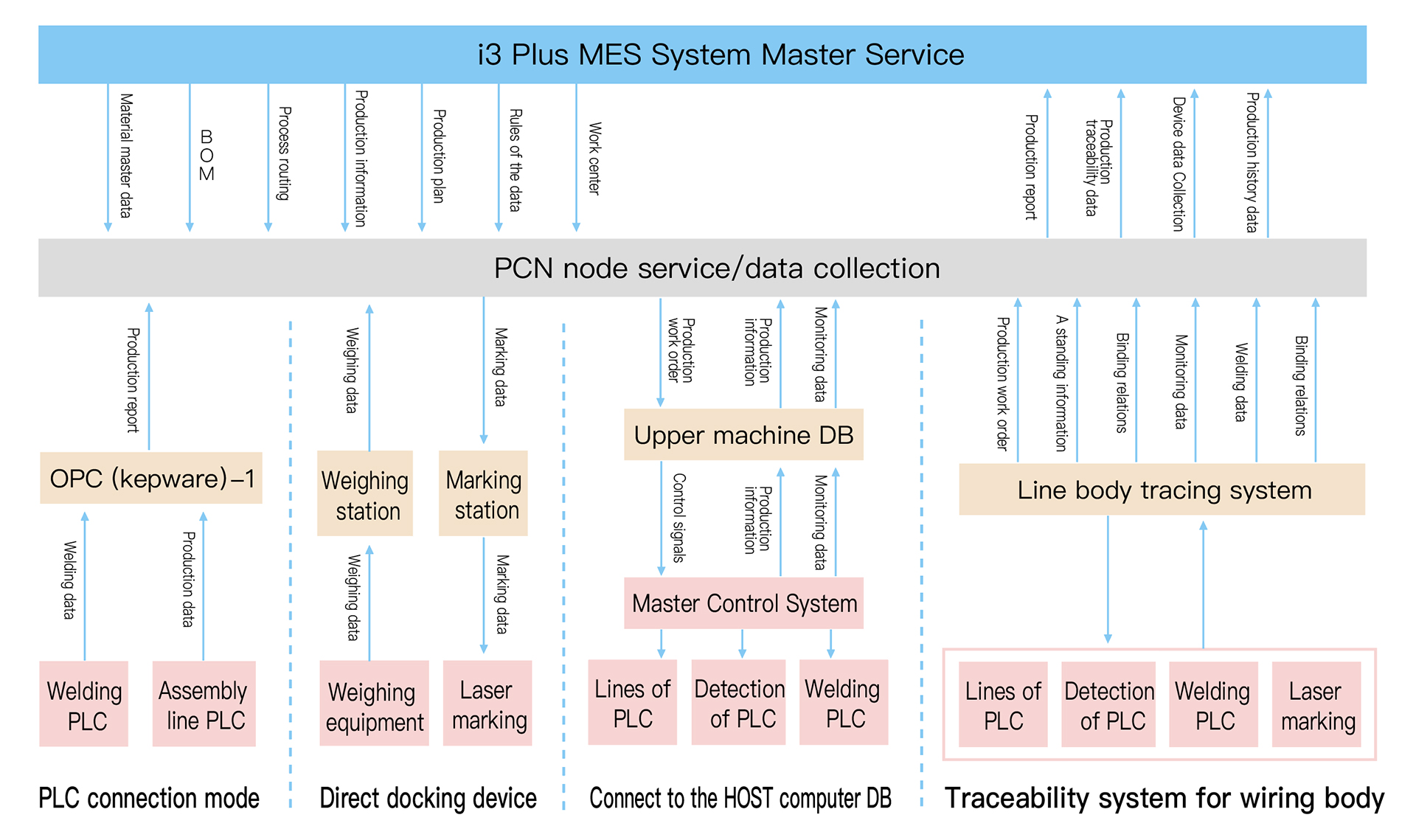

According to the requirements of intelligent manufacturing, the project implementation of equipment data acquisition system mainly includes the following contents:

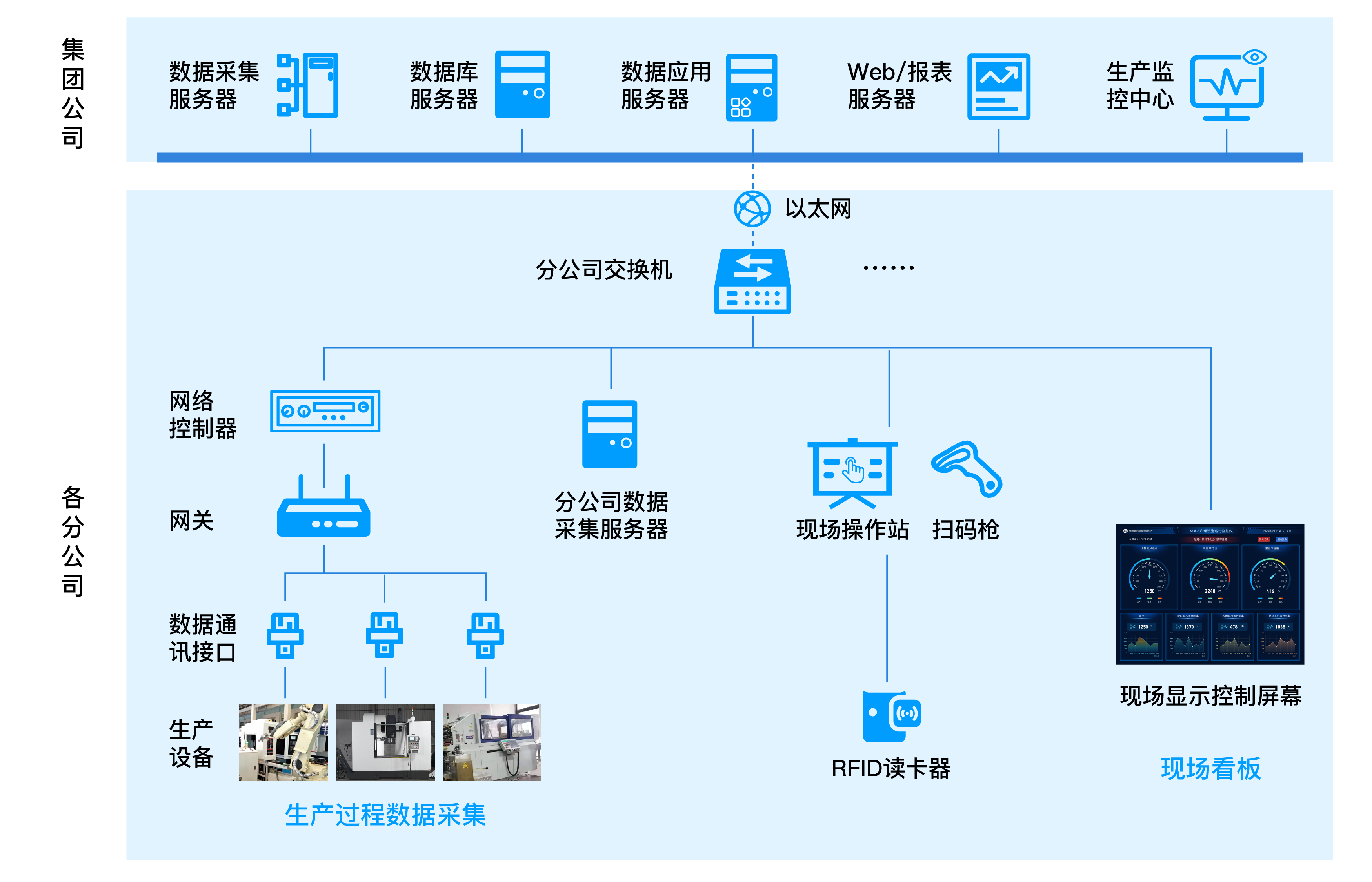

· The network center should be set up in the headquarters of the group company, and all branches in the headquarters of the group company will be directly connected with the network center;

· Establish real-time database, transform data communication interfaces of various production equipment, unify data communication protocol specifications, and collect data of PLC (programmable logic controller), sensors, controllers, actuators, online testing instruments, intelligent instruments and other control systems and equipment of on-site production equipment. Including control parameters, process parameters, output data, equipment operation records, logistics information, storage data, product quality data, energy consumption data, etc;

· Establish industrial historical database to store historical data, and conduct data analysis, query and statistics on production and equipment conditions; Production management personnel, professional and technical personnel, workshop management personnel through remote access to understand and analyze the production process;

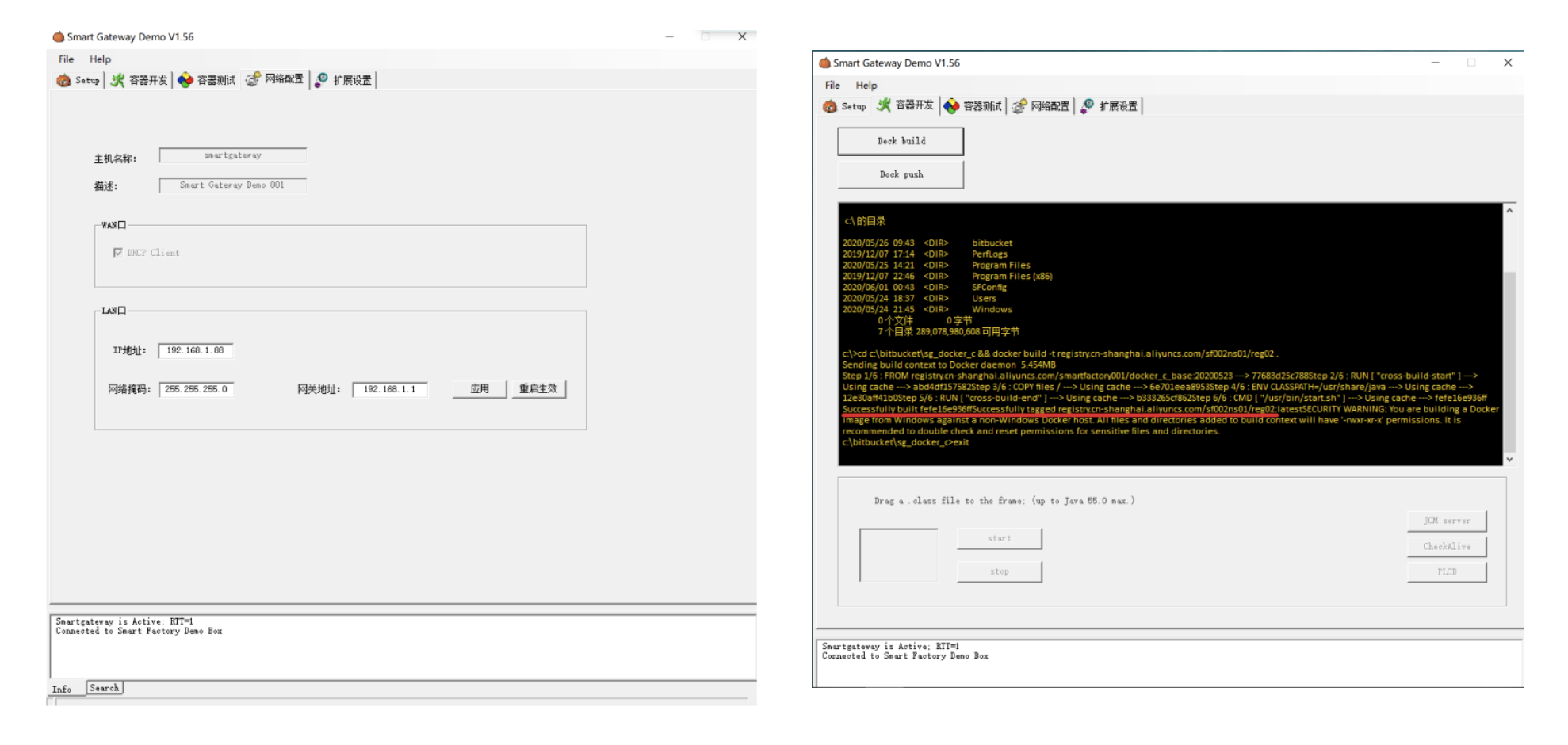

· The operation interface of the production site operation station is designed to realize the man-machine interaction between the operator and the production system. The operation interface includes main menu, process monitoring, real-time trend, historical trend, real-time alarm, report query, equipment operation and other screens to realize the real-time monitoring of the production process;

· Big screen monitors display main process parameters and equipment running status in real time;

· The data acquisition system is integrated with ERP, MES and other information systems to realize data interconnection between each other.

· Production process data acquisition

Quality data collection: various test results, product defects, adverse treatment measures;

Production data: work order information, output information, various production process data;

Material data: material batch, material status;

Personnel data: personnel information, shift and group information, commuting information;

Equipment data: equipment status, operating parameters, equipment processing data;

Tooling data: working status, tooling usage;

· Create more economic benefits for processing and manufacturing enterprises

Improve the intelligent degree of machines and equipment;

Reduce labor cost and improve production efficiency;

Monitor and analyze the energy consumption of manufacturing, analyze and improve the economic performance of machines and equipment;

Provide complete, accurate and reliable real-time data, upgrade production management;

Distributed data collection, processing, generation of historical database, statistics, analysis, report, graph, record; Display and release information according to position and authority; Push information to remind related staff to deal with the lack of material, quality, failure and other events; Exchange data with ERP and other systems;

Real-time monitoring, storage, statistics: start and stop record, working, standby, breakdown, maintenance, trial and other status and duration;

Real-time calculation and analysis: OEE at different levels of equipment, production line, workshop, etc. Calculate and analyze the operation economic performance of production equipment; Calculate and analyze various production performance indicators according to user needs.