股票代码:833352

中文|

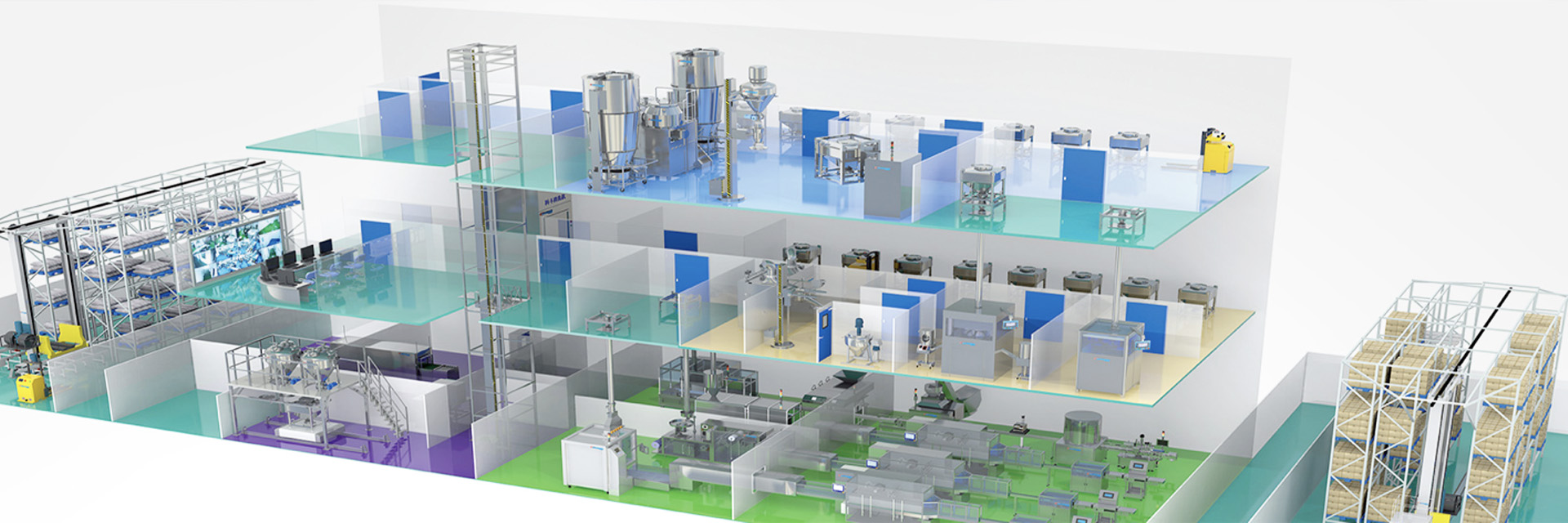

One large auto parts group company was founded in 1997 in Shanghai, the company's business covers Cockpit assembly, mechanical parts, Seat foaming, Seat cover, headrest and crown system, etc.,From the main automobile manufacturers cluster in the country to establish factories, to provide customers with zero-distance real-time supply and service. At the same time, the company has entered the global procurement system of many multinational automobile enterprises, to provide international customers with products and services beyond expectations.The company's own enterprise informatization construction strategic objectives and customers' requirements for informatization interconnection, quality traceability and other aspects, combined with the characteristics of numerous subsidiaries and branches, informatization level and management system and versions of branches and subsidiaries are different. The group decided to build a new information management platform, including warehouse management WMS, production management MES, MRP material demand planning, order management, supplier management, quality management, sales management and other functional modules. The system platform can be flexibly and effectively deployed in each branch company to achieve comprehensive information unified management.

Solution:

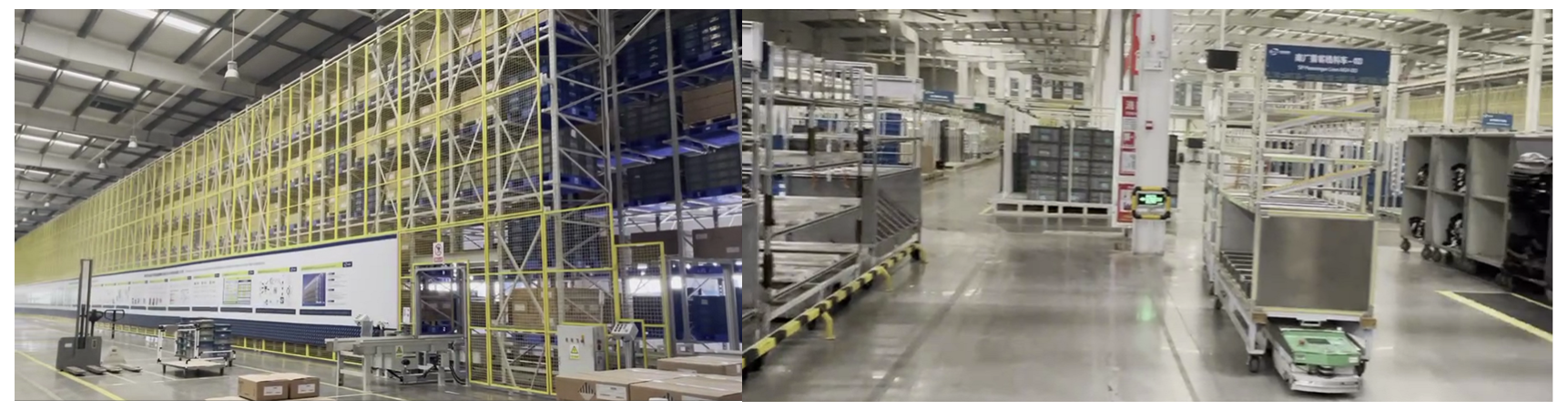

· Based on i3Plus product platform, build a highly integrated warehouse management platform

The platform integrates ERP, AMP, ASRS, AGV automatic scheduling, QMS, TMS and other information products, comprehensively breaking the isolated information island, and realizing the data instantly available after searching.

· Centralized cloud deployment

Through Ali Cloud to build enterprise cloud-warehouse, the group internal information data are transparency;

Highly availability cloud services, realizing the rapid horizontal expansion of intelligent warehousing;

High availability of data can be achieved by separating master/slave, dividing table/library, hot/cold processing, etc.

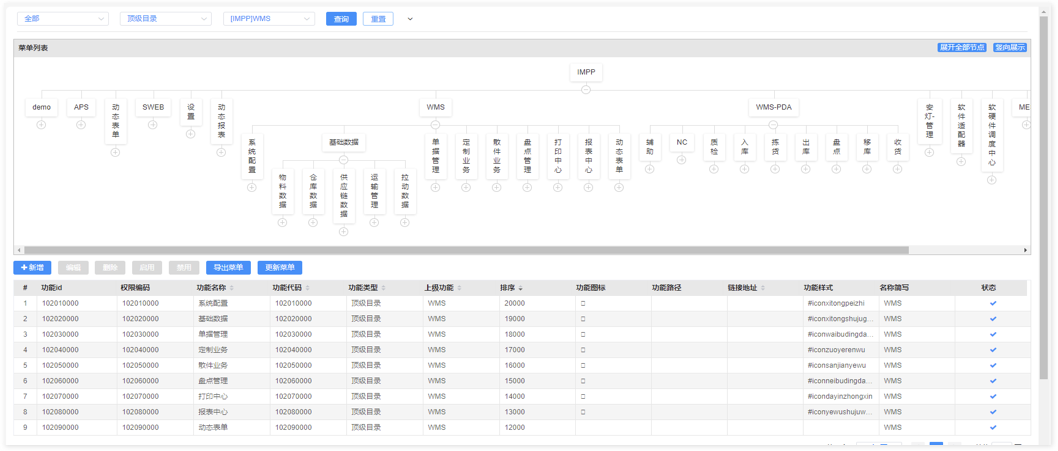

· Meet actual needs flexible through multi-level permission control mechanism

Roles are assigned in accordance with the organization structure;

Design and distribute the corresponding business modules in accordance with the job role;

Granularity of authority control meets various control requirements on site, and covering operation level authority.

· Standardized business specifications

Products collecting a large sum of manufacturing business scenarios, supporting various business requirements by default;

The precise delivery of logistics can be achieved through three-level strategy management.

· Internal pulling between factories

To achieve rapid logistics settlement among factories under the group, and support various methods of down-line settlement and ingredient settlement;

Set the rules of material warehousing, such as quick warehousing, wave distribution and logistics route, etc.

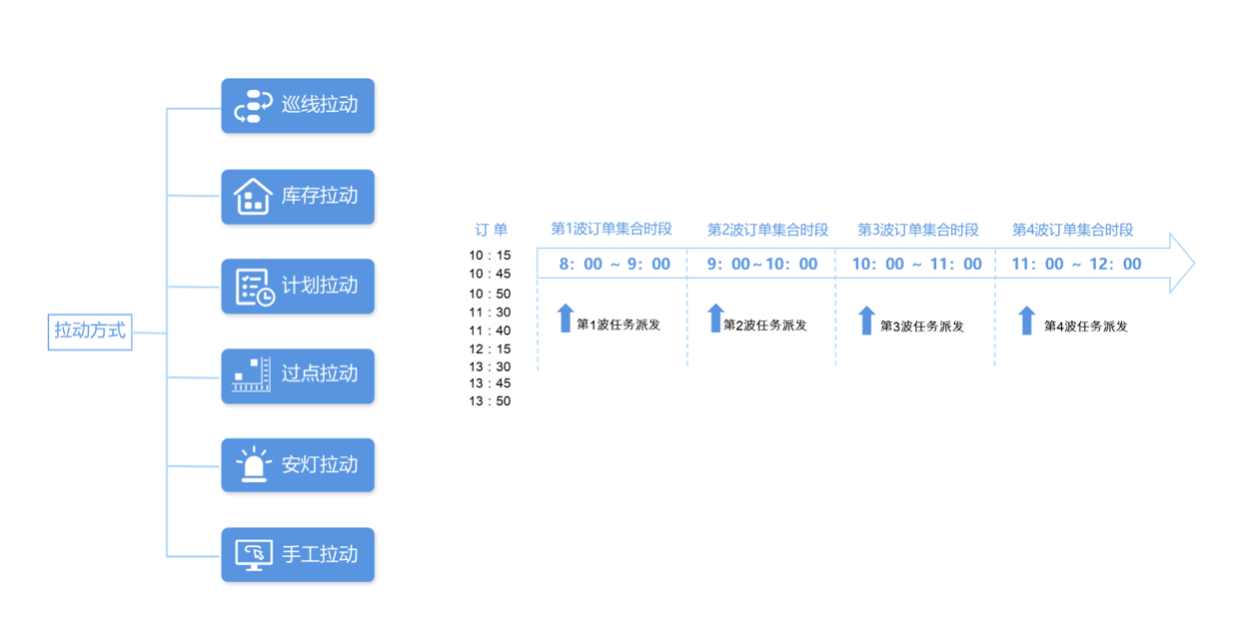

· Various material pulling modes

Scenario

-The storage area replenishes the kanban shipment area

-The storage area replenishes the JIS area

-Replenishment from storage area to processing area in warehouse.

Execute

-Picking area setting

Not all parts need replenishment

-Trigger on demand

-Replenishment according to available space

Avoid overloading

-Support for handheld devices and task management

Efficiency

- Improve the response speed of distribution

- Improve warehouse utilization/staff efficiency

Strategy

-Material selection rules for replenishment

· Planning engine - Storage optimization

Regularly analyze goods flow, ABC analysis and inventory location adjustment

Condition

-Moving goods fast

-Close to shipping docker or main passageway

-Cargo weight considered

-To meet the requirements of ergonomics

Goal

-By shortening the distance, optimize the picking performance