股票代码:833352

中文|

Customer requirements:

SAIC group belongs to a auto parts group to carry out the informatization construction, based on intelligent manufacturing project progress, to enhance and improve the production process data acquisition requirements, equipment data acquisition gradually become enterprise production monitoring and important data to support decision, industrial field intelligent data acquisition terminal of Internet of things platform plan, Remote data collection, remote download and remote maintenance can be realized conveniently. Support a variety of industrial equipment driver protocol, multi-channel communication interface, can meet most of the industrial controller equipment networking requirements.

Supports multiple Internet access modes and cloud servers. The remote management platform can be directly used to implement remote configuration, diagnosis, and management.

Solution:

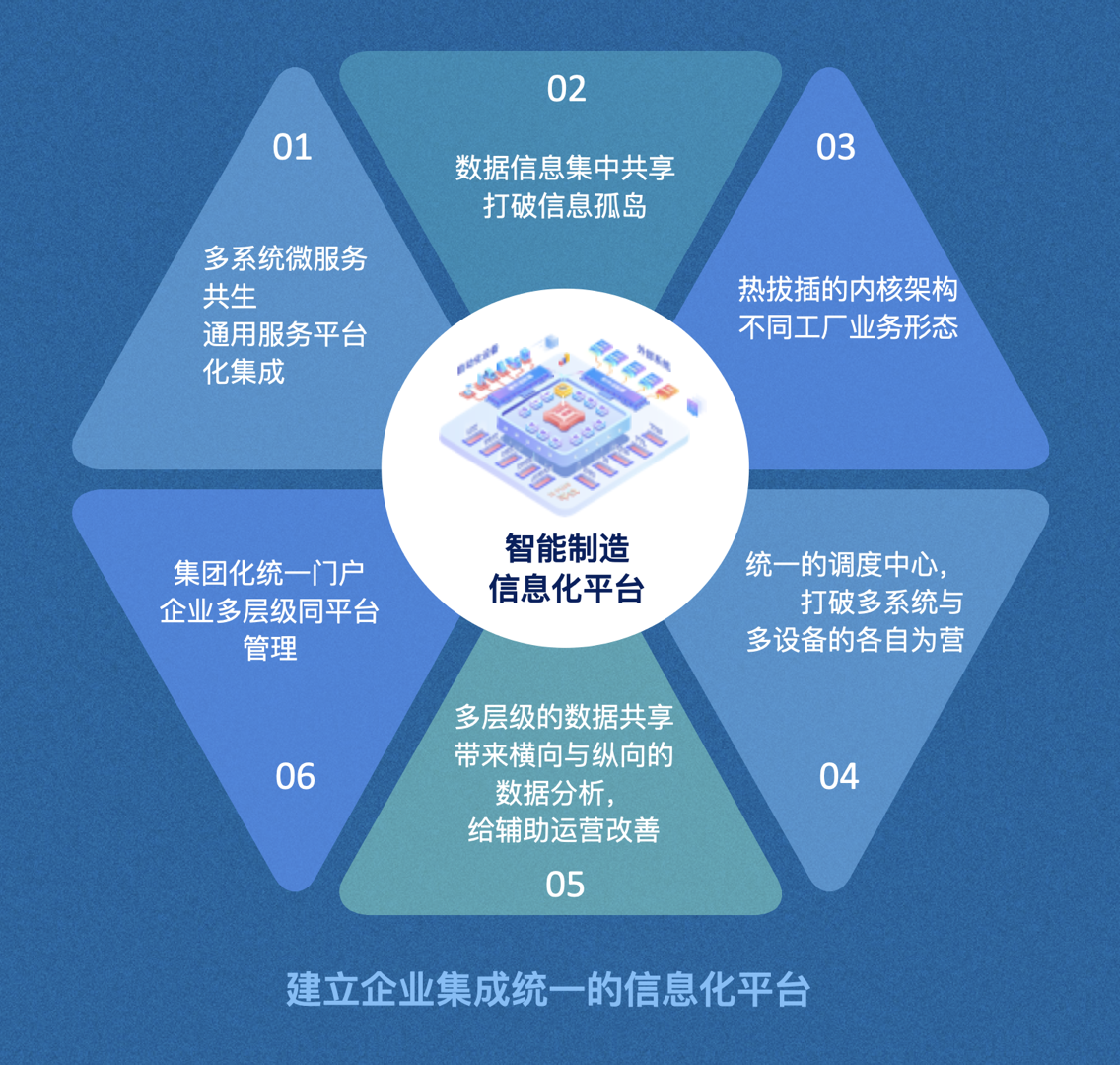

·Equipment data acquisition intelligent platform

Automatic collection of production, quality, equipment status and energy consumption data of production equipment (machine tools, robots), testing equipment, logistics equipment (AGV, vertical storage, forklift, etc.);

i3 Plus intelligent workshop platform is used to achieve integrated platform management of production and manufacturing, warehouse management, automation equipment integration, data acquisition and analysis, data center, etc.

·Intelligent manufacturing data analysis

Manufacturing enterprises usually need to monitor, manage and analyze the data of the production process, product quality and equipment operation and maintenance, and use intelligent analysis, intelligent warning and intelligent forecast to achieve intelligent manufacturing management, reduce physical and mental labor, and greatly improve labor productivity.

·Index monitoring and data tracing

Monitor the usage of analysis indicators to see whether all analysis indicators are in use, or whether someone is using the indicators that others have abandoned, so as to ensure the validity of data maintenance;

Complete data link monitoring, realize production, quality, process and other comprehensive data monitoring and traceability, real-time control of production status.

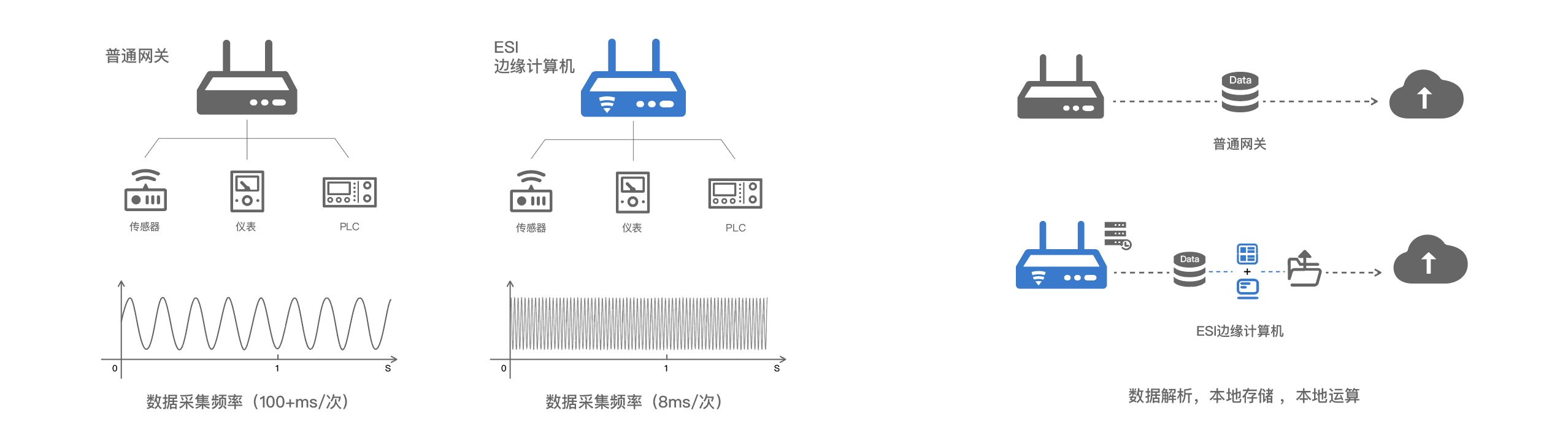

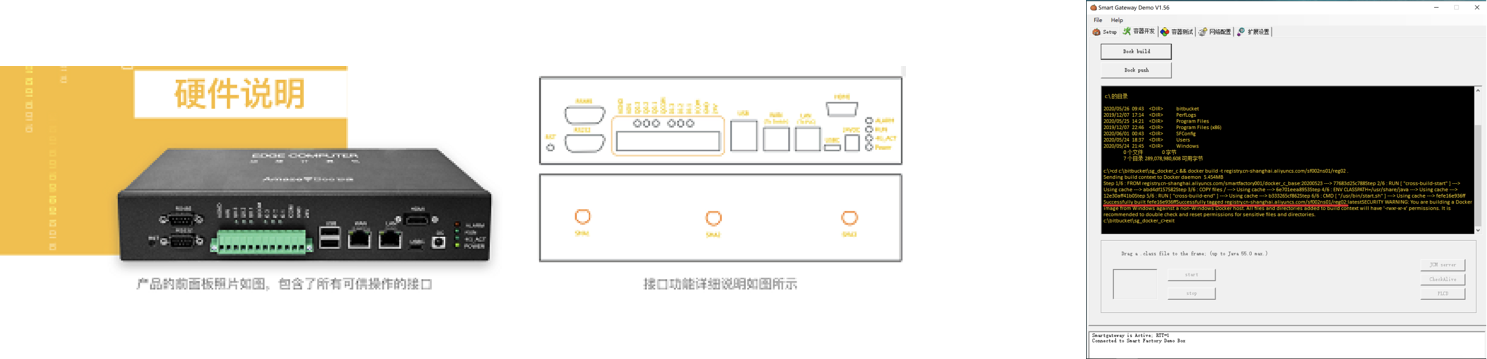

· Edge calculation + equipment number acquisition terminal

Support PLC, ModbusRTU, ModbusTCP, Profibus and other industrial equipment and protocol connection and data collection;

Local data analysis, support cloud server pushing;

Supports containerized computation;

Supports cross-platform development ;

Supports cloud data interconnection and mobile data interconnection;

Support edge calculation, 12000MIPS or above;

Supports remote management tools, remote configuration and diagnosis;

Support local caching of historical data.

·Improved management philosophy

Advanced industry management concept based on automation and informatization.

Business process oriented, high quality and efficient delivery as the goal;

Through integrated informationization, cultivate employees' global awareness and overall operation;

Through the unified information platform and strengthen the multi-department communication and coordination, to avoid information asymmetry caused by information and data blocking, affecting the unified decision;

Establish the brand intelligent manufacturing high-tech enterprise image, is conducive to enterprises to obtain more orders and product promotion.