股票代码:833352

中文|

Customer requirements:

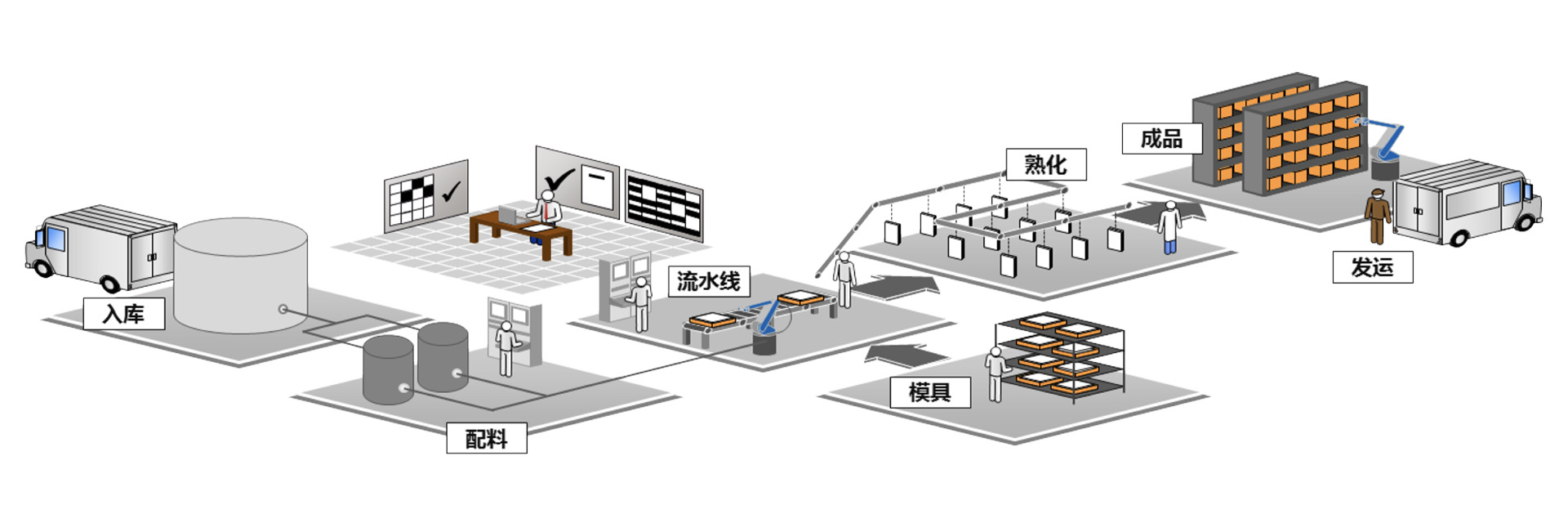

A large automotive manufacturing group company in Shanghai, focusing on automotive interior and exterior decoration, seat, electronics and passive safety fields, is committed to providing leading product solutions for the world's major automotive manufacturers, overseas business accounts for nearly 30%, more than 220 factories all over the world. With the deepening of enterprise informatization construction, the requirements of production and manufacturing process management, informatization integration and traceability are gradually increased.

For foaming business unit, it is expected to improve the overall competitiveness by building intelligent production line management; The specifications of the production line are very high, especially a centralized production control system, which can control all the functions of the production line, such as foaming equipment (measuring equipment, mixing head and perfusion manipulator), polymerized curing mold and mold frame, etc., at one point.

Solution:

· Production modeling

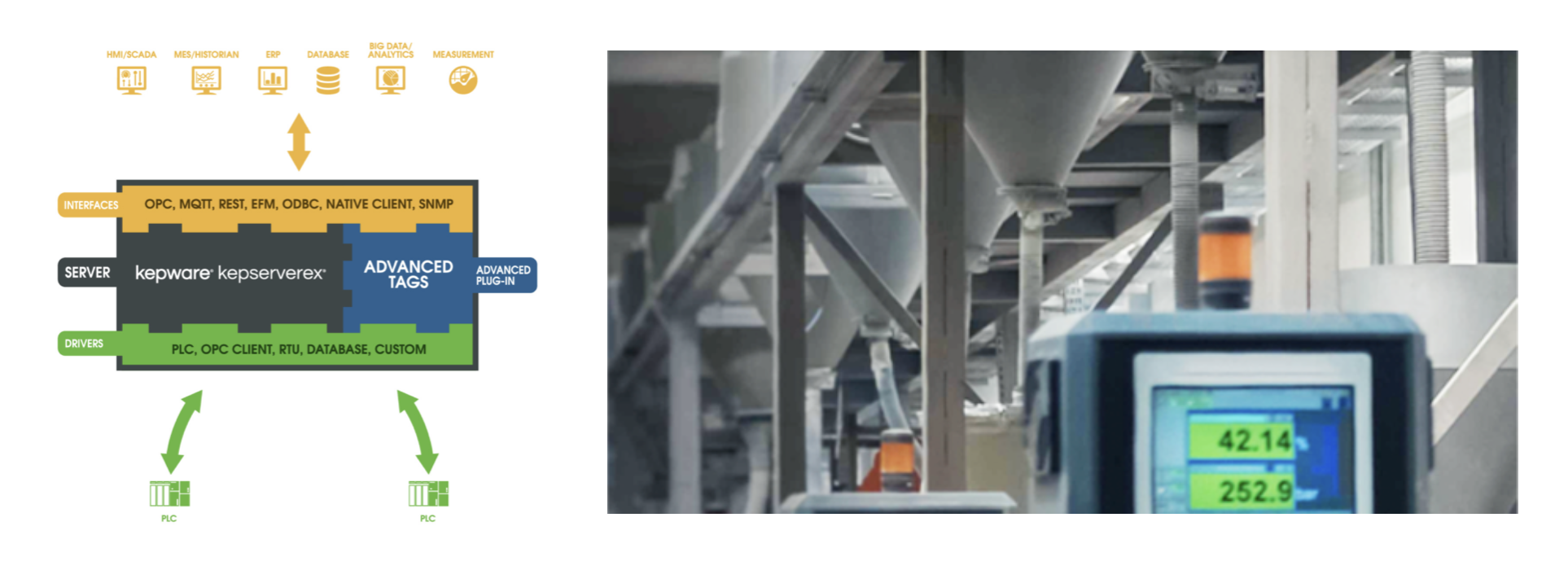

Factory model: define factory, workshop, production line, data collection point and workstation information, etc.

Process path & Rules: the system supports the configuration of different production lines and products of the production process path and work steps (rules), so as to achieve the same platform to support production management of different factories, production lines and different products.

Data collection rules: The system can configure verification, conversion, and matching rules for the data collected in the production process, for example, barcode verification rules for raw materials, and conversion of device data to system standard format rules, so as to meet the data collection requirements for different products on different production lines.

· Material pulling

Material pulling: Pre-production material preparation process: the system generates material demand and distribution task according to the audited production work order. Batcher or AGV delivers materials according to the distribution task. After completion, the inventory of the line will increase. Feeding during production: the system monitors the line-side inventory, when it is lower than the safety inventory, it automatically generates the material pulling task according to the rules and pushes it to the batcher or AGV, and the line-side inventory increases after the material is delivered.

Urgent pulling:In case of shortage of material due to abnormality (such as raw material damage, missing distribution, etc.), the staff can call the material through the system, and the logistics personnel will send the missing material to the shortage station immediately according to the system prompt after receiving the urgent pulling demand.

Lineside storage management: the system supports the line storage out of storage, in storage, material scrap, return and other operations

Demand mode & rule: the system supports the rules of material requirement generation, group mode, distribution mode (manual, AGV), etc., so as to meet the different distribution mode of different materials.

· Equipment management

Device check criteria: define different check criteria for different types of devices, such as pre-check items, error prevention items, etc

Routine check plan: define the check plan rules of the equipment, the system will automatically generate check tasks and send them to the relevant person, such as check the equipment within half an hour after work, check the error prevention every 2 hours, check the measuring tools after 1000 pieces are processed, etc.

Equipment OEE: from the production process of tracking and control module for equipment output and plan production time, the quality of the product was obtained from the process quality management module, from the equipment state module to get the actual boot outage time, equipment and equipment technical indexes of information, such as computing equipment OEE, and through the visual kanban display.

· Process quality management

Quality problem acquisition & tracking: by manually or automatically from the device will produce quality problems in the process of the method of record and in binding products have quality problems of products do not allow the door through quality control points, quality problems have been fixed after need to record time to repair, repair, repair station, repair results, such as information is used to track the query.

Key indicator SPC analysis: By selecting SPC analysis parameters, such as product type, time period, indicator and sample size, the system will automatically analyze the corresponding X-R graph, histogram, dot graph, CP value and CPK value, etc

· Early warning Management

Manual & automatic warning: when employees find abnormal, the system will trigger the alarm immediately. The system will analyze and check the data according to the customized rules, and automatically warn when the abnormal is found, for example, when the FTQ value is less than 98%

Different types of warning rules can be defined, such as the person or role who needs to be notified by email or SMS. Content of the notice; How long to upgrade; Whether to fill in the handling measures

· Visualization

Production real-time kanban: real-time display of [current product], [planned number], [completed number], [FTQ], defect number bar chart, etc

The current warning information kanban, such as warning time, calling station & person, warning type, response time, responder, will be highlighted in red on the warning board

· ODS

Document management: The system can store product information (such as work instructions, inspection standards, training videos, etc.) in the system through interface or batch import mode.

Data display: through the interface of the production line, the production staff can check all kinds of data related to the current product at any time. You can also display current product information through electronic kanban instead of paper version information.

· Trace query

Product traceability: query all production process information of the product by product unique code, including production start and completion time, equipment processing and testing data, key material data, equipment mold information, personnel information, etc.

Processing and testing data traceability: support the backward tracking of which products' processing and testing data meet certain conditions.

Material tracking: users can query the product information by the unique code or batch of the material.

Device trace: support backward trace to find the products processed by a device in a certain period of time.

Personnel traceability: Supports backward traceability to query which products a person produced in which position over a certain period of time.